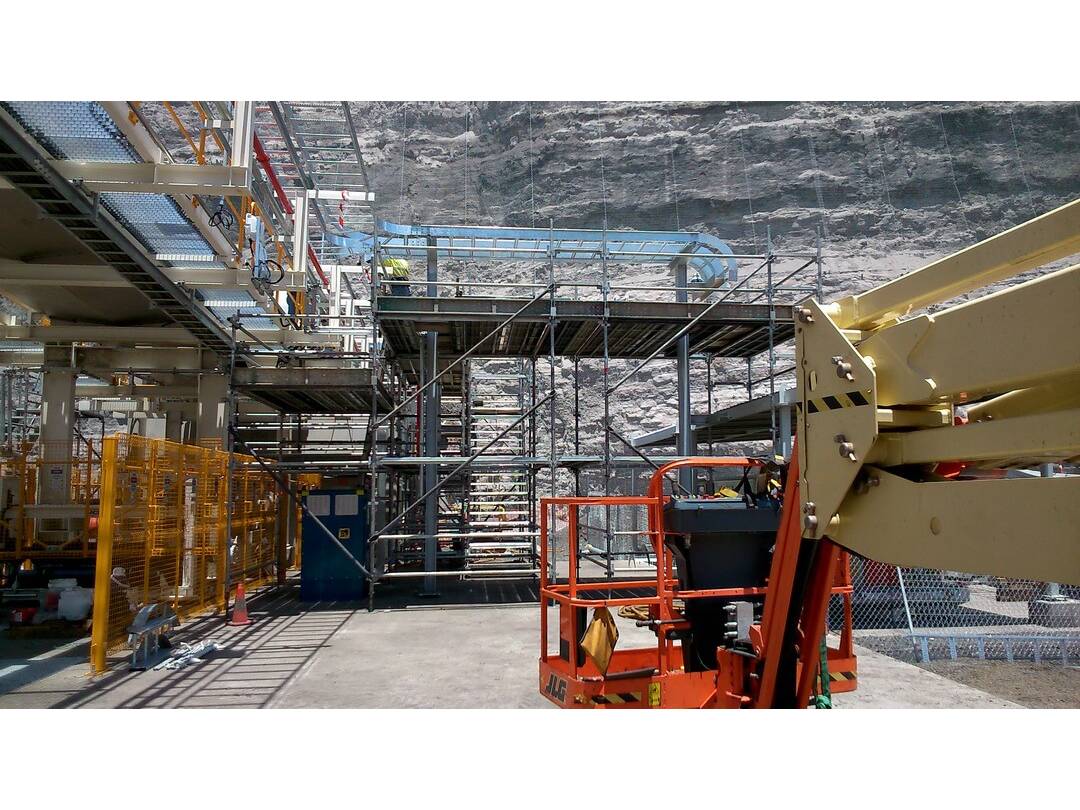

BMA Broadmeadow – MG10 & MG11 Conveyors

- Client:

- BM Alliance Coal Operations Pty Ltd

- Duration:

- 7 Months

- Completed:

- January 2014

As BMA’s Broadmeadow longwall mine operations advanced, a need was identified to install new conveyer infrastructure to replace shuttle cars and diesel ram cars to transport coal from the face.

Walz Group was engaged by BMA to complete the structural, mechanical and pipework installation of two new conveyers — Maingate 10 (MG10) and Maingate 11 (MG11). The project was completed in two stages — one for each conveyor — to accommodate operational constraints. We undertook all installation and construction work required to complete both conveyors.

Works were conducted in a live operating environment to maximise operational efficiency. This required careful planning and sequencing to ensure the mine could continue to operate as usual, safely and with minimal impact on production.

Specifically, the works incorporated:

- Coffin seals

- Drive frames

- Drive modules

- Belt maintenance equipment

- Substation shed and related interface structures

- Grouting to all structures including drive areas and transfer foundations

- Hand rails

- Transfer towers

- Gantries and trestles and their associated mechanical components